| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : HL

Model Number : HL-PET

Certification : CE SGS

Place of Origin : CHINA

MOQ : 1 Set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 50set/month

Delivery Time : 50~55 working days

Packaging Details : plastic film

Name : pet strap manufacturing machine

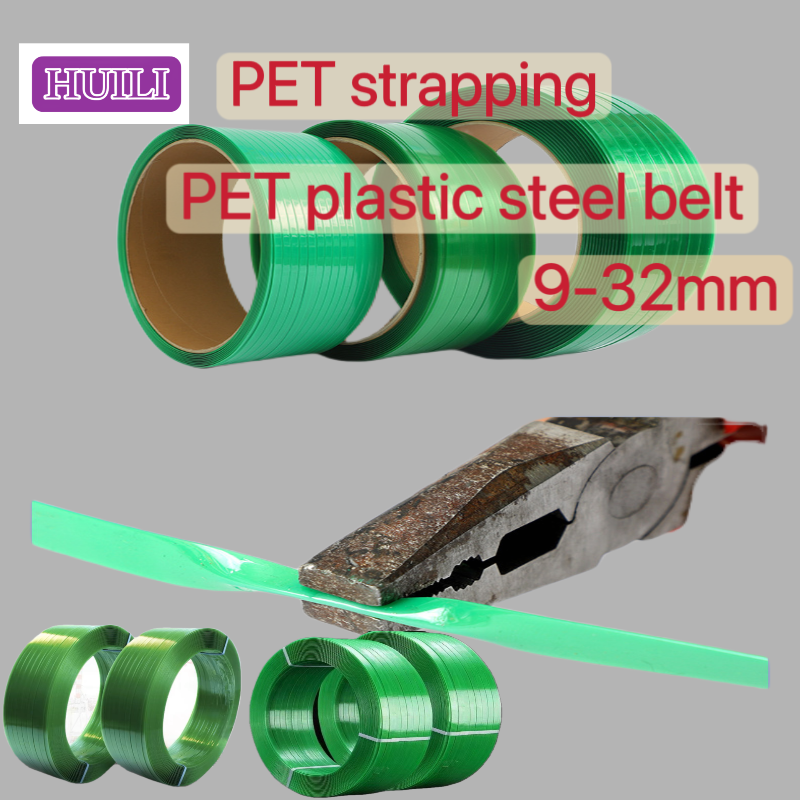

Strap Width : 9-32 mm

Strap Thickness : 0.6-1.2 mm

Paper tube size : Ø406*180 mm

Metering melt pump : 100 CC

Screen changer : chemical fiber filter

Control mode : PLC

Extrusion method : High speed

Not easy to break : YES

Wrapping machine : Automatic/semi-automatic

Line speed : 100-250 m/min

Automation : automation PET

PP/PET belt making machine 9-25mm PET plastic steel belt production line high-speed dehumidifier

FEATURE DESCRIPTION OF PET BELT MAKING MACHINE

PET strap manufacturing machine/PET belt making machine

pet strap manufacturing machine (equipment used to produce or use PET plastic strapping) has the following characteristics:

FEATURES:

Stretching------PET plastic steel belt equipment adopts a unique two-time stretching process, the strip has good steeliness, stable width, and improved tensile strength of the finished product.

Components-----PET plastic steel belt equipment adopts high-precision components to ensure stable product molding quality, and the fluctuations in width and thickness are far less than the national standard;

Oven-------PET plastic steel belt equipment adopts a unique oven circulation heating system, and adopts a reciprocating winding method inside, which fully utilizes heat energy and greatly reduces power loss.

PET strapping production line process flow

① Loading →② Mixing raw materials →③ Pre-drying raw materials →④ Vacuum dehumidification of raw materials →⑤ Melting and metering extrusion of raw materials →⑥ Cooling and forming of raw materials (strips) →⑦ Preheating in the oven →⑧ Primary stretching →⑨ Secondary stretching →⑩ Embossing →⑪ Oven tempering and shaping →⑫ Cooling →⑬ Finished product winding

Raw materials---------

100% PET bottle flakes or crushed materials

EXTRUSION PARAMETERS TABLE

| Model | PET-2 | PET-3 | PET-4 | PET-6 | PET-8 |

| Raw materials | 100% Bottle flakes/crushed materials | ||||

| Number of tapes | 2 | 3 | 4 | 6 | 8 |

| Width (mm) | 9-32 | ||||

| Width (mm) | 0.4-1.2 | ||||

| Maximum line speed(m/min) | ≧150 | ≧150 | ≧150 | ≧150 | ≧150 |

| PLC control system | PLC | PLC | PLC | PLC | PLC |

| Screw Model | 90 | 100 | 125 | 150 | 180 |

| Reducer model | 200 | 250 | 280 | 315 | 350 |

| Dryer tank | 3000L | 4000L | 5000L | 6000L | 6000L |

| Dehumidifier | 1000 | 1000 | 2000 | 3000 | 3500 |

| Metering Pumps | 100CC | 100CC | 100CC | 100CC | 100CC |

| Screen Changer | Single cylinder | ||||

| Winding machine | Automatic winding/ Semi-automatic winding | ||||

| Production capacity /24 H | 5-6T | 7-8T | 10-12T | 12-15T | 18-20T |

Advantages of finished PET strapping:

**Key Advantages:**

High Strength and Impact Resistance:

PET strapping boasts extremely high tensile strength, approaching that of steel strapping of the same specifications, with some models even comparable to steel strapping. It is approximately twice as strong as PP strapping. Simultaneously, it exhibits excellent impact resistance and ductility, effectively cushioning vibrations and impacts during transportation, reducing the risk of breakage due to bumps and ensuring the safety of goods during transport.

-----

The winder adopts double-station winding device, torque motor control, simple operation and convenient roll changing.

After-sales service

PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of pet strap manufacturing machine.

2. Analysis of finished product manufacturing costs of PET strap manufacturing machine.

3. Analysis of raw materials used in PET strap manufacturing machine.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET strap manufacturing machine.

2. Installation, commissioning and training of PET strap manufacturing machine.

3. Maintenance service of PET strap manufacturing machine.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET strap manufacturing machine?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET strap manufacturing machine?

A: Different models have different extrusion capacities, with capacities ranging from 150-600KG/H

Q: What is the producible width of the PET strap manufacturing machine?

A: 9-32mm

Q: Can the PET strap manufacturing machine be customized?

A: Customization supported

Q: Where does the PET strap manufacturing machine come from?

A: China.

Q: What are the certifications for the PET strap manufacturing machine?

A: ISO CEO certification.

Q: What is the minimum order quantity for the PET strap manufacturing machine?

A: 1 set

Q: What is the weight of the PET strap manufacturing machine?

20T, 40GP container * 3PCS

|

|

PP PET belt making machine 9-25mm PET plastic steel belt production line high-speed dehumidifier Images |